Lift Removal for Replacement Projects

Lift removal is often required as part of a replacement project when an ageing or unreliable lift reaches the end of its life, or when it no longer suits the needs of the building. Many assume the process is simply the reverse of installation, but safe removal is far more complex and must be carefully planned.

This guide explains how lift removal works, what influences cost, the key safety considerations, and when replacement might be the more effective long-term option for your building.

What Is Lift Removal?

Lift removal is the controlled process of dismantling and safely disposing of a lift and its associated components. It is typically required when a lift has reached the end of its working life.

Because lift removal involves heavy equipment, electrical isolation, and potentially hazardous materials, it must always be carried out by qualified professionals with the correct training and certifications.

Invalifts does not offer lift removal as a standalone service; removal is undertaken only where it forms part of a wider lift replacement or upgrade project.

Who Should Remove a Lift?

Lift removal should only be carried out by a specialist team, typically the same contractor responsible for installing the replacement lift, to ensure continuity. Qualified engineers understand how to identify and manage hazardous materials in line with COSHH requirements, and beyond the technical work, a professional team can coordinate permits, control risks in occupied buildings, and maintain safe access around the site throughout the removal process.

The Eight-Step Lift Removal Process

When a lift is being replaced, removal of the existing equipment follows a structured process to ensure safety, compliance, and readiness for the new installation. Although every site is different, the process typically follows these eight core steps:

1. Initial Assessment & Survey

A specialist team surveys the lift, shaft, motor room, and surrounding structure. This identifies access constraints, the lift’s condition, and any hazardous materials such as hydraulic oils or potential asbestos within older components.

2. Planning & Risk Assessment

A detailed method statement is prepared, covering hot works permits, fire safety coordination, scaffolding for safe access, and fall protection at each landing. In occupied buildings, the plan also considers noise, dust control and restricted access to work zones.

3. Disconnection & Safe Isolation

Engineers isolate power, remove fuses, and safely disconnect electrical and mechanical systems to eliminate risk during dismantling.

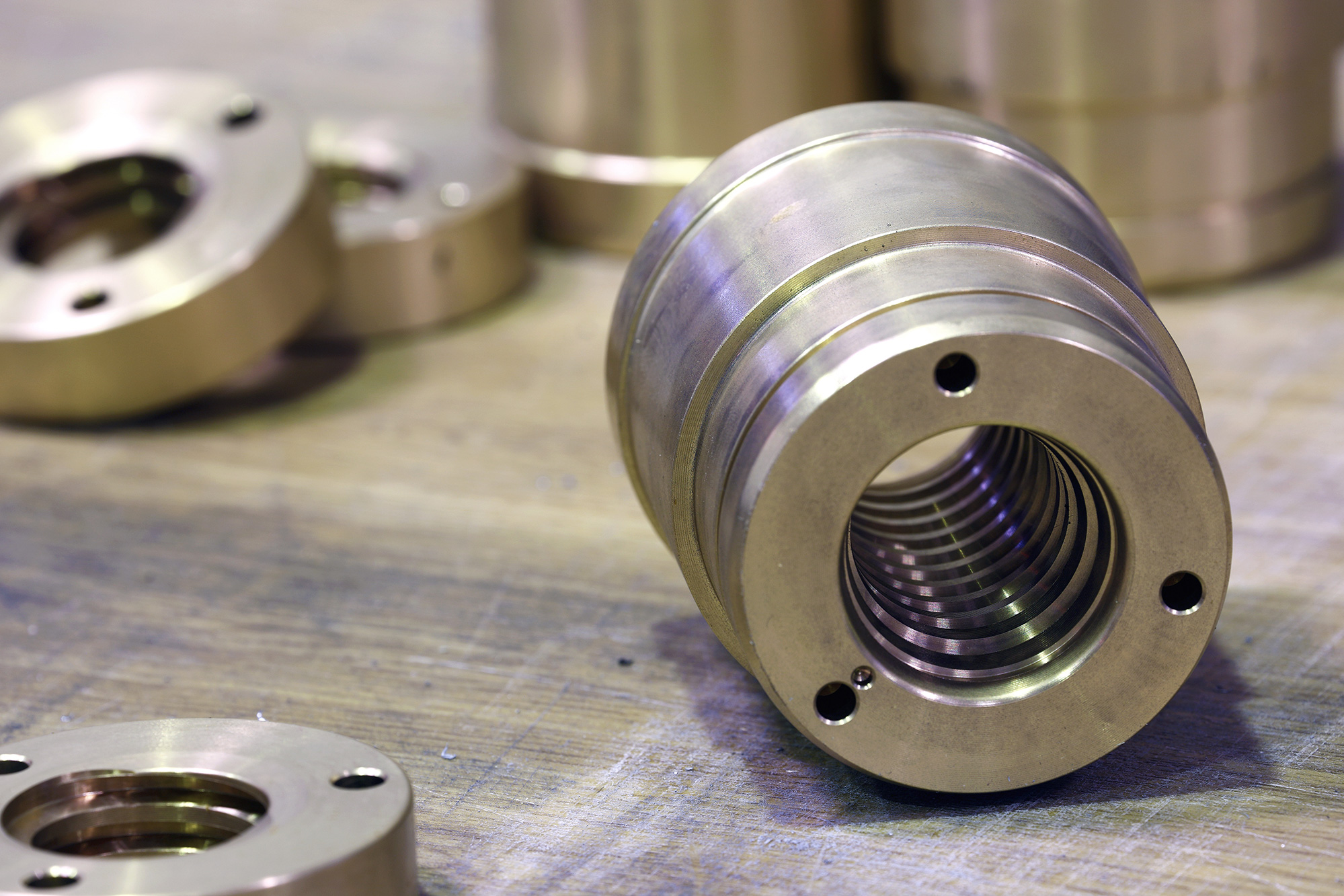

4. Dismantling Lift Components

The cabin or platform, guide rails, door gear, and controller are dismantled systematically. Cutting tools may be required, triggering hot works procedures and fire-watch measures.

5. Lowering Heavy Equipment Safely

Heavy machinery such as motors and drive assemblies must be lowered from the top of the shaft using specialist lifting equipment. In some cases, components may be left in situ if removal would require major demolition.

6. Removal of Hazardous Waste & Debris

Accumulated waste in old pits can include sharp objects, biological waste or oils, all of which require controlled disposal under COSHH regulations.

7. Safe Disposal & Recycling

Components are segregated for recycling wherever possible, and controlled waste (such as oils, electrics, or asbestos-containing materials) is removed by licensed carriers.

8. Making the Site Safe Post-Removal

Once dismantling is complete, engineers secure all landings, remove temporary access equipment, and ensure the area is safe for continued building use or for installation of a replacement lift.

Why Lift Removal Requires Careful Planning

Lift removal is far more involved than many expect, largely due to the safety and environmental considerations that arise once dismantling begins.

- Hot works, such as cutting through steel components, must be tightly controlled – often requiring permits, fire-watch procedures, and coordination with building management.

- Older lifts may contain asbestos within brake assemblies, insulation, or controller units, while hydraulic systems can hold oils or fluids that must be treated as controlled waste.

Working within the shaft itself presents additional risks:

- Fall protection at every landing is essential, especially in occupied buildings where access routes need to remain secure.

- Noise and disruption must be managed sensitively, with work areas isolated to protect staff, residents, or visitors.

- Dust is another concern – disturbing long-unopened shafts can release harmful particulates and accumulated debris.

- Lift pits frequently contain hazardous waste, from sharp objects to biological matter such as decomposed rodents or contaminated materials. Each of these risks requires strict handling and disposal procedures.

These complexities are why lift removal must be meticulously planned and carried out only by trained professionals who can manage safety, environmental controls, and compliance from start to finish.

How Much Does Lift Removal Cost?

The cost of removing a lift varies significantly depending on several key factors. These include the type, size, and weight of the lift, as larger units require more time and specialist equipment to dismantle. The travel height also affects complexity, as taller shafts involve more labour and safety controls.

Access constraints, particularly in occupied, heritage or space-restricted buildings, can influence both time on site and the resources required.

Costs may increase where hazardous materials such as asbestos, hydraulic oils, or contaminated waste are present, as these demand licensed handling and disposal. Waste management more broadly (steelwork, electrical components, and accumulated debris) also forms part of the overall cost.

Where removal forms part of a replacement project, costs can often be managed more efficiently, as planning, labour, and access arrangements are shared across both stages. A precise cost can only be confirmed following a professional site survey.

Can You Repair a Lift Instead of Removing It?

In some cases, a failing lift can be repaired rather than removed, particularly when issues are isolated or parts are readily replaceable. However, if the lift is consistently unreliable, obsolete, or no longer compliant with modern standards, repair may not be cost-effective.

Invalifts engineers can assess the condition of the lift and advise on the most practical route forward.

Can the Existing Shaft or Footprint Be Reused?

In many cases, yes – an existing shaft or footprint can be reused, which helps reduce building work and speeds up installation. Modern platform lifts are often designed to fit within older lift spaces, making replacement far simpler than a full structural alteration.

Invalifts can carry out a detailed survey to assess the shaft’s suitability, check clearances, and structural conditions – and recommend the most appropriate replacement lift for your building’s needs.

How Invalifts Can Assist Your Lift Removal

With over 25 years of experience, Invalifts manages lift removal as part of a wider replacement or upgrade project, alongside nationwide installation of modern access solutions. Our specialist engineers coordinate removal and installation together, ensuring minimal disruption and a smooth transition to a new lift system.

If you’re considering replacement options – including platform lifts, step lifts, stairlifts, and cabin lifts – we offer a free, no-obligation survey to guide your decision. Get in touch to discuss your project.

FAQs About Lift Removal

How long does lift removal take?

The duration depends on the lift size, travel height, and site conditions, but many removals can be completed within a few days.

Can a lift be removed while the building is in use?

Yes — where removal forms part of a replacement project, strict safety controls allow work to be carried out safely in occupied buildings.

Do I need permits for lift removal?

Certain activities, such as hot works, waste handling, or work in heritage buildings, may require permits. A specialist removal team will identify and manage all necessary permissions.

Is lift removal noisy or disruptive?

Some noise and disruption is unavoidable, particularly when cutting steel components or moving heavy machinery. Engineers plan work to minimise impact and isolate the area where possible.

Can the old lift be recycled?

Yes. Many components, including steelwork and electronics, can be recycled. Hazardous materials and oils must be handled separately and disposed of by licensed carriers.

What happens if hazardous materials are found?

If asbestos, contaminated waste, or hydraulic oils are identified, trained specialists follow strict COSHH procedures. These materials are removed safely and disposed of in line with environmental regulations.